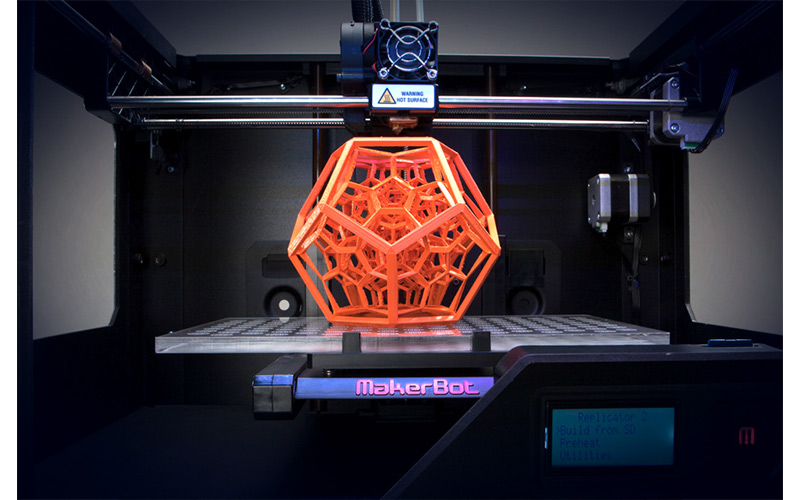

This course is designed to enhance the creativity and technical skills of materials, 3D concepts, model designing, computer aided designing, real world objects creation, machines, manufacturing, motor skills, prototyping and new technology adoption. Courses are aimed for colleges, university students, Students will be taught to ‘think and solve in 3D’.

Our 3D Printing experts love to help you optimize the quality of your prototypes and parts, and maximize the throughput of your 3D Printer.

Many Colleges invest in 3D printing for one application, then realize the technology has many more uses. Expert training in FDM Technology can help you expand the value of 3D printing beyond basic applications. You might be surprised at what 3D printing can do.

3D printing is by far one of the most interesting and happening technological advancements that mankind has seen in almost a decade. 3D printing has proved to be a booming industry in the west and in most developed countries. But in India and other developing countries, 3D printing technology adoption is a bit slow. Given the 1.2 billion population, 3D printing shall provide Indians with lot of opportunities and also improve Indian economy.

Industries and institutions are fast adopting 3D Printing. They employ engineers and designers with 3D printing training as prototype and product engineers. 3D Printing experts are employed in design houses that provide 3D design, 3D computer-aided design (CAD) modelling, biological and scientific modelling, and architecture/construction modelling services.

Contact UsDirector- Innovations, Disruptive Innovation Group, Valuelabs, Hyderabad.

A prolific inventor and passionate engineer, Ravi brings with himself 13 years of experience in the R&D and innovation arenas. He has worked extensively in the nuclear, aerospace and defence, oil and gas, and aviation (both government and corporate) domains.

Ravi has worked with Atomic Energy Regulatory Board Mumbai, Cyient Limited Hyderabad, Motivitylabs Hyderabad in various leadership roles. As an engineer & scientist and a business leader, Ravi has developed first-of-their-kind methods, algorithms and products across various engineering disciplines.

Ravi is a well-known innovation guru and universal mentor for young engineers from premier India institutions. His solution approaches have, time and again, been appreciated in national as well as international open innovation challenges for addressing global problems. He is one among the few innovation professionals in India who specialize in problem identification and problem definition for IP creation. An active evangelist for nation building through IP creation, Ravi has been associated with national as well as international advisory scientific and engineering committees.

Ravi has been the recipient of numerous awards / rewards for his par excellence scholastic achievements namely the Chief Minister’s Andhra Pradesh Gold Medal in 1997, the Institution of Engineers Award in 1999, the AERB Fellowship in 2005, and the ANSYS Best Paper award in 2013. He has also been a finalist in the CII Innovation Awards 2014, the HYSEA Awards 2015, the Altair Best Poster Award in 2015, and the Best Paper award in 2015 from Warse. Additionally, Ravi has been a speaker at national and international forums on engineering innovation and leadership and has published 70 papers in national and international conferences and journals. He also has multiple patents to his credit. He has written a book on One India-N Zeros.

Ravi holds an M.Tech Degree from the Indian Institute of Technology, Mumbai and a Bachelor’s Degree in Mechanical from Osmania University, Diploma in Automobile Engineering Masabtank polytechnic.

The course is of 7 weeks, With 3 Hour Classes on friday's and saturday's.